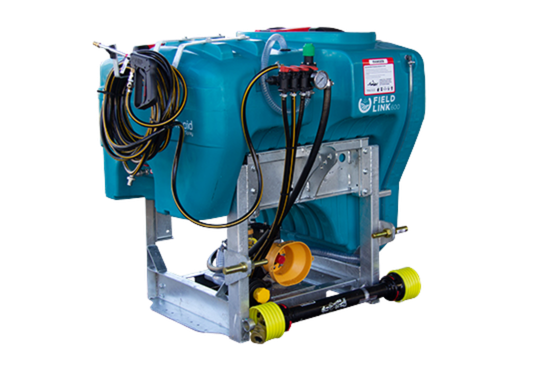

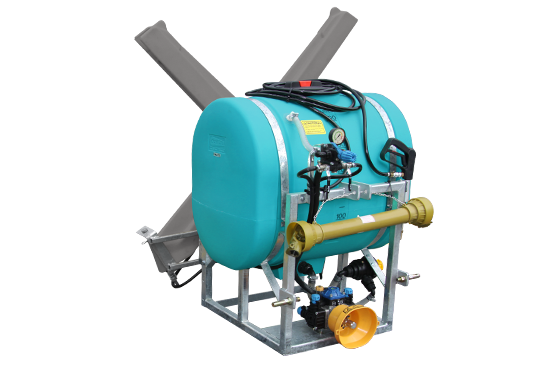

300L SprayLink 3-Point Linkage Sprayer

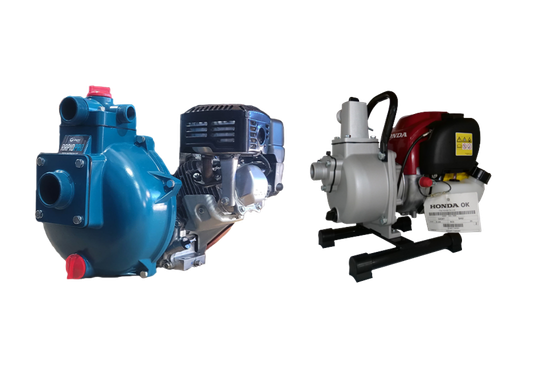

With the powerful, Italian Bertolini pump, the higher flow rate is perfect for larger boom spraying!

VIEW PARTS BREAKDOWN VIEW SPARE PARTS

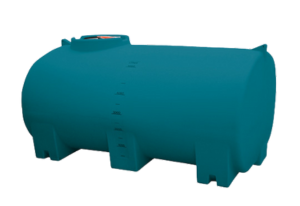

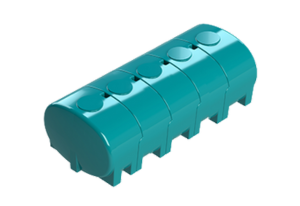

- UV stabilised polyethylene tank

- 22L/min 290psi Bertolini pump

- 6m x 10mm spray hose

- Powerjet spray gun

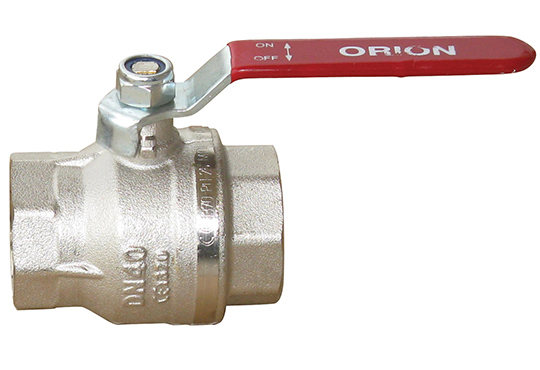

- Pressure regulator & gauge

- 4m Poly boom with non-drip nozzles

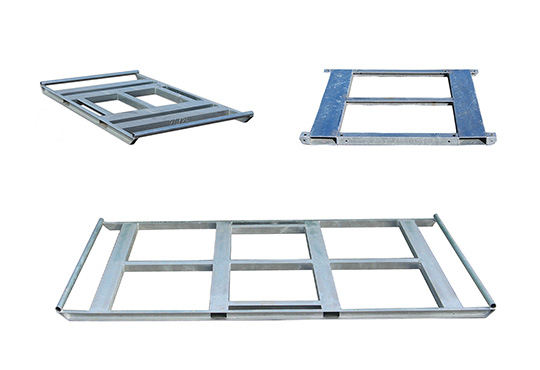

- 3-point-linkage galvanised steel frame

- Category 1 linkage pins

- Fully draining sump tank

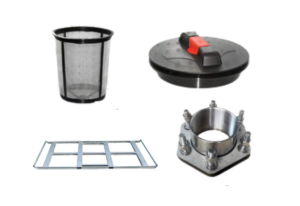

- 250mm screw lid

- Anti-spill lip around lid

- Basket filter to reduce debris

- PTO shaft

These units are manufactured to order. Please contact us for manufacturing times or stocking dealers.

$5,879.00

What Should I do before Operating?

WARNING: Do not operate the tractor PTO until correct fitting has been checked. Doing so will damage your pump and tractor. This will also void your warranty.

When operating a PTO shaft, ensure the following:

• Wear tight fitted clothing while connecting and disconnecting your sprayer.

• Shut off tractor and remove the keys before connecting or disconnecting PTO to pump.

• Do not reach over the back of the tractor to adjust the PTO or throttle.

• Never step over a revolving PTO shaft even if shielded.

• Do not operate PTO shaft without guards, damaged guards or using the restraining

members correctly attached; ensure guards are in place while spraying.

• Do not expose guarded parts of the shaft by cutting or enlarging grease access holes.

• PTO shafts and safety clutches have to match the power take off and the machine type.

See the instructions with your machine for recommended type and size of shaft and

clutches. Overload can cause damage.

• Do not operate above recommended speeds. No device (e.g. adapters) shall be

installed between the tractor PTO and the PTO drive shaft. No changes may be made to

the PTO drive shaft and it’s guard, except in length adjustment.

Why choose Rapid Spray 3PL sprayers?

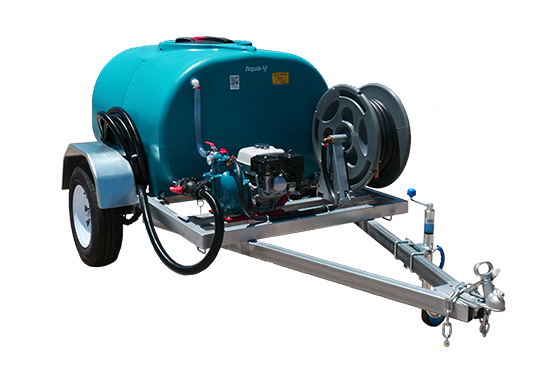

Experience unmatched stability and control with Rapid Spray’s linkage sprayers. Our secret weapon? The innovative, specially contoured tank design. This unique feature hugs the back of your tractor, creating a lower center of gravity for exceptional stability. Say goodbye to bouncing and swaying, even on uneven fields or rough terrain.

Focus on the job at hand with a smoother ride, allowing for precise and efficient spraying. Rapid Spray linkage sprayers are built with the toughest materials and construction for season after season of reliable performance, making them the perfect partner for your toughest jobs.

What is a three-point linkage (3PL) sprayer?

A three-point sprayer, also known as a 3-point linkage sprayer, 3pt sprayer, or 3pl sprayer, is a workhorse attachment designed for tractors. These sprayers utilize a three-point hitch system to connect securely to the back of your tractor. This stable connection allows for efficient liquid application across large fields.

How do you hook up a 3PL sprayer?

Watch the video on how to cut your PTO shaft.

WARNING: : Do not operate the tractor PTO until correct fitting has been checked. Doing so will damage your pump and tractor. This will also void your warranty.

While the exact steps might vary depending on your specific tractor model, here’s a general guide for hooking up a 3-point sprayer:

- Lower the Lift Arms: Park your tractor on level ground and engage the parking brake. Lower the tractor’s hydraulic lift arms (also sometimes called hitch arms) completely.

- Attach Lower Link Arms: Connect the lower link arms of the 3-point sprayer to the corresponding points on your tractor’s lift arms. These connection points typically use pins and clevises.

- Connect Top Link Arm: Locate the top link arm on the sprayer and connect it to the top link attachment point on your tractor. There may be an adjustable turnbuckle on the top link for fine-tuning the sprayer’s position.

- Hydraulic Hoses: Connect the hydraulic hoses from the sprayer to the corresponding hydraulic ports on your tractor. These hoses typically control functions like the pump and boom movement.

- Raise the Lift Arms: Once everything is securely connected, slowly raise the tractor’s hydraulic lift arms to lift the sprayer off the ground. Double-check all connections and for any leaks before starting spraying operations.

Important Note: Always refer to your tractor’s user manual and the specific instructions for your Rapid Spray linkage sprayer model for detailed and accurate hook-up procedures. For safety reasons, it’s recommended to have someone assist you when connecting the sprayer for the first time.

What are the available tank capacities for Rapid Spray's 3PL sprayers?

Rapid Spray offers 3-point linkage sprayers in capacities ranging from 400L to 800L. These models are designed to meet the needs of different farm sizes and spraying requirements.

Are there different models available?

Yes, Rapid Spray provides two main models:

FieldLink Eco: The base model suitable for standard spraying needs.

FieldLink Pro: An upgraded version featuring additional features like a flush tank and multi-controller for enhanced functionality.

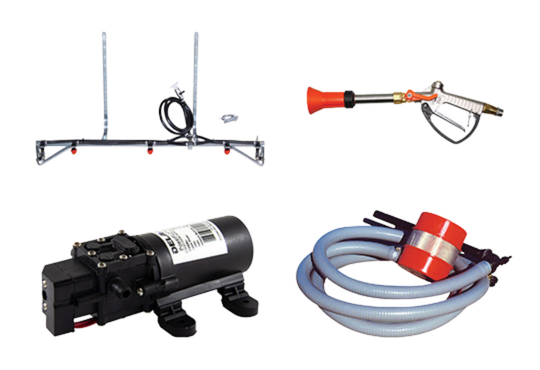

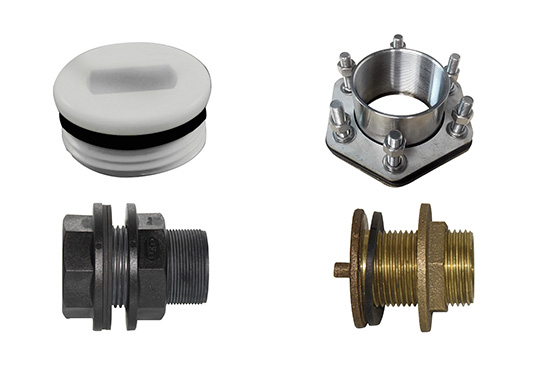

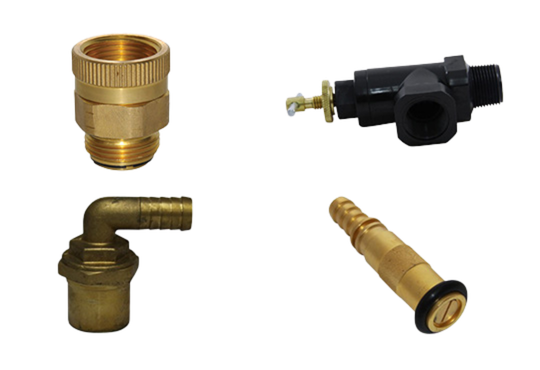

What accessories are available for these sprayers?

Rapid Spray offers a range of accessories to customize your sprayer, including:

Hand wash tanks

Hose reel upgrades

Flat-fold steel booms

These accessories allow operators to tailor their sprayer setup for convenience, efficiency, and precision in different spraying applications.

How do I maintain and clean the sprayer?

Maintenance and cleaning are crucial for the longevity of your sprayer. Rapid Spray recommends:

Regularly flushing the system after use to prevent chemical residue buildup.

Inspecting hoses and nozzles for clogs or wear.

Storing the sprayer in a dry, sheltered area to protect it from environmental damage.

For detailed maintenance procedures, refer to the operator’s handbook provided with your sprayer.

What is the warranty period for Rapid Spray 3PL sprayers?

Rapid Spray offers a 25-year warranty on the UV-stabilized polyethylene tanks of their 3-point linkage sprayers, reflecting their commitment to durability and quality.

Can 3PL sprayers handle different chemicals?

Yes, but always check chemical compatibility with tank and hose materials to prevent corrosion or damage.

Are 3PL sprayers easy to maneuver?

Generally, yes – they are compact and follow the tractor’s movements, making them suitable for smaller paddocks, uneven terrain, or narrow rows.