- Products

- Parts

- Parts Kits

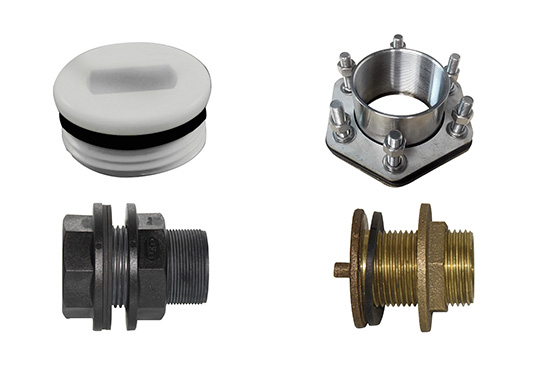

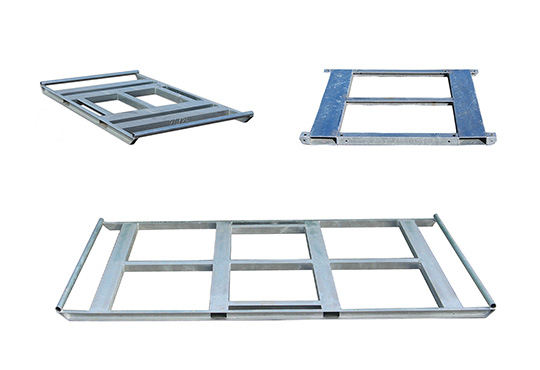

- Tank Parts

- Spray Equipment

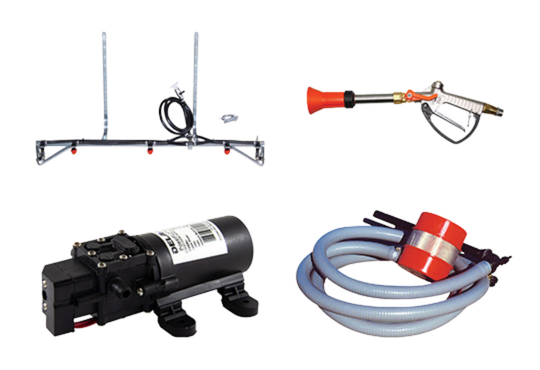

12V Pumps, parts & accessories

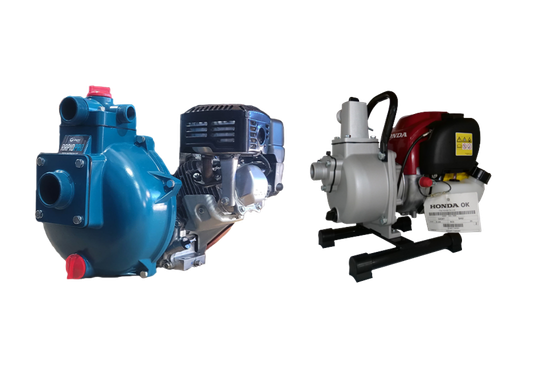

12V Pumps, parts & accessories Engine & PTO Drive Pumps, parts & accessories

Engine & PTO Drive Pumps, parts & accessories Hose Reels & Parts

Hose Reels & Parts Spray Guns, Lances & Accessories

Spray Guns, Lances & Accessories 12 Volt Spot Sprayer Parts & Accessories

12 Volt Spot Sprayer Parts & Accessories Backpack, compression & trolley sprayer parts

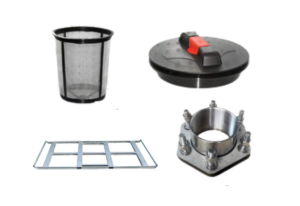

Backpack, compression & trolley sprayer parts Spray Tank Lids, basket filters & outlets

Spray Tank Lids, basket filters & outlets nozzles, boomless nozzles & boom accessories

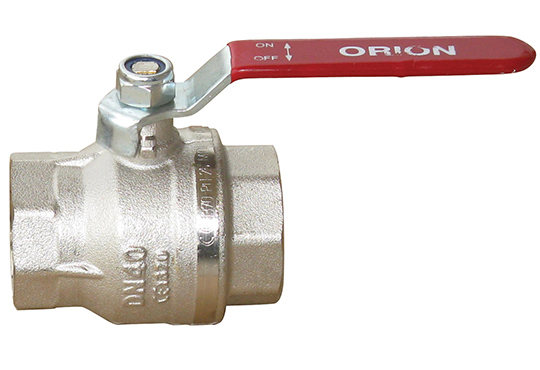

nozzles, boomless nozzles & boom accessories Other Spray Parts & Accessories

Other Spray Parts & Accessories Batteries & Chargers

Batteries & Chargers

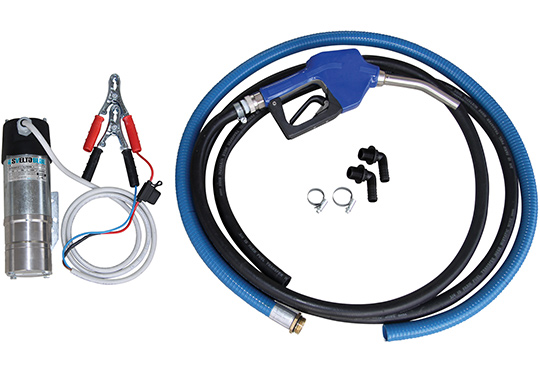

- Diesel Refuelling Parts

- Fire Fighting Parts

- Mining & Industrial

- STOCKING DEALERS

- Resources

- Customer Hub

- Specials

- Contact Us

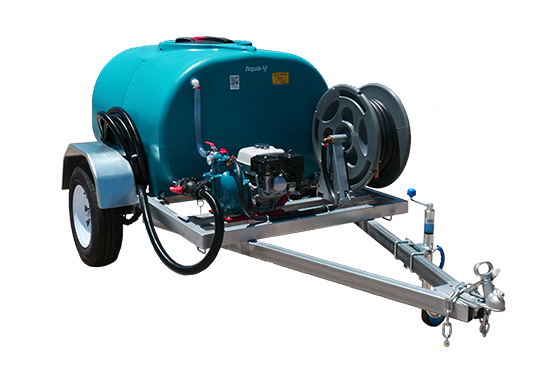

A boom sprayer is one of the most effective tools for applying herbicides, fertilisers, and other liquid treatments evenly across large areas. Used extensively in agriculture, turf management, councils, and commercial property maintenance, boom sprayers are designed to deliver consistent spray coverage while maximising efficiency and reducing chemical waste.

This guide explains what a boom sprayer is, how it works, where it is best used, and how to choose the right setup for Australian conditions. Whether you are managing acreage, sports fields, paddocks, or commercial land, understanding boom sprayers will help you achieve better spraying results with less effort.

What Is a Boom Sprayer?

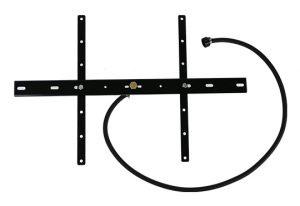

A boom sprayer is a spraying system that uses a horizontal bar, known as a boom, fitted with multiple spray nozzles spaced evenly along its length. As liquid is pumped through the system, each nozzle releases spray at a controlled rate, creating uniform coverage across a wide area.

Boom sprayers can be:

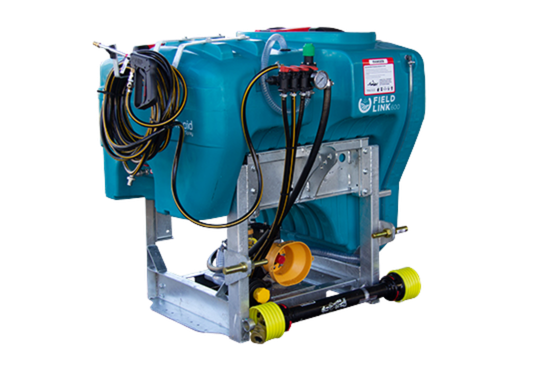

Mounted on vehicles, utes, or trailers

Fitted to ride-on mowers

Integrated into water carts or spraying units

Used in agricultural or turf applications

They are designed to apply chemicals evenly and accurately over broad areas, making them ideal for large-scale spraying tasks.

Why Use a Boom Sprayer?

Boom sprayers are widely used because they provide unmatched consistency and efficiency when spraying large areas.

Even Coverage

One of the main benefits of a boom sprayer is uniform application. With evenly spaced nozzles, boom sprayers:

Deliver consistent spray patterns

Prevent under or over application

Improve chemical effectiveness

This is critical when applying fertilisers or selective herbicides that rely on accurate dosing.

Increased Efficiency

Boom sprayers allow operators to:

Cover wide areas quickly

Reduce spraying time

Minimise refills

Lower labour costs

This makes them ideal for commercial operations and large properties.

Reduced Chemical Waste

Accurate application helps:

Reduce chemical runoff

Minimise overspray

Lower overall chemical usage

Protect surrounding vegetation

Common Uses for Boom Sprayers

Agriculture and Farming

Boom sprayers are commonly used in agriculture for:

Broadacre weed control

Crop spraying

Fertiliser application

Pasture management

They are well suited to open paddocks and flat terrain where consistent coverage is required.

Turf and Lawn Management

In turf applications, boom sprayers are used on:

Sports fields

Golf courses

Large residential lawns

Commercial landscapes

They provide even coverage that helps maintain healthy turf and consistent growth.

Councils and Government Applications

Local councils use boom sprayers for:

Park and reserve maintenance

Roadside vegetation management

Public land spraying

School and facility grounds

Boom sprayers help councils manage large areas efficiently while maintaining safety and compliance.

Commercial and Industrial Properties

Boom sprayers are also used for:

Industrial estates

Large commercial sites

Warehouse surroundings

Infrastructure corridors

Types of Boom Sprayers

Fixed Boom Sprayers

Fixed boom sprayers have a rigid boom width and are ideal for:

Flat, open areas

Consistent spraying patterns

Repeatable applications

They are commonly mounted to trailers or vehicles.

Folding Boom Sprayers

Folding boom sprayers allow the boom arms to fold in when not in use.

Advantages include:

Easier transport

Reduced storage space

Less risk of damage when moving between areas

These are popular for users who need flexibility.

Adjustable Boom Sprayers

Adjustable boom systems allow operators to:

Change boom width

Adjust nozzle spacing

Modify spray height

This flexibility is useful when spraying different types of areas or vegetation.

Boom Width and Coverage Considerations

Boom width plays a major role in performance.

Common boom widths include:

Narrow booms for ride-on mowers and compact setups

Medium-width booms for acreage and turf

Wide booms for large paddocks or commercial operations

Choosing the right width depends on:

Area size

Terrain

Vehicle or mower capacity

Transport and storage requirements

Wider booms increase efficiency but may be harder to manoeuvre in tight spaces.

Nozzles and Spray Patterns

Nozzles are critical to boom sprayer performance.

Common nozzle types include:

Flat fan nozzles for herbicides

Low-drift nozzles for windy conditions

Fertiliser-specific nozzles for liquid nutrients

Correct nozzle selection helps:

Improve spray accuracy

Reduce drift

Match chemical label requirements

Protect non-target plants

Regular inspection and replacement of nozzles ensures consistent performance.

Boom Sprayer vs Boomless Sprayer

While both systems are effective, they serve different purposes.

Boom sprayers are best for:

Flat terrain

Wide open areas

Even and consistent coverage

Boomless sprayers are better for:

Uneven ground

Obstacles such as trees and rocks

Fence lines and road edges

Many operators choose one based on terrain or use both for different applications.

Calibration and Setup Best Practices

Correct calibration is essential for effective spraying.

Calibration involves:

Setting the correct pressure

Choosing the right nozzle size

Measuring output per minute

Matching travel speed to application rate

Proper calibration ensures:

Effective weed and pest control

Reduced chemical waste

Compliance with chemical guidelines

Regular calibration checks help maintain accuracy over time.

Safety Considerations When Using a Boom Sprayer

Safety should always be a priority.

Best practices include:

Wearing appropriate personal protective equipment

Following chemical label instructions

Avoiding spraying in high winds

Maintaining safe distances from people and animals

Cleaning equipment after use

Responsible spraying protects the operator, the environment, and surrounding vegetation.

Maintenance Tips for Boom Sprayers

Routine maintenance helps extend the life of the sprayer.

Key maintenance tasks include:

Flushing the system after each use

Cleaning filters and strainers

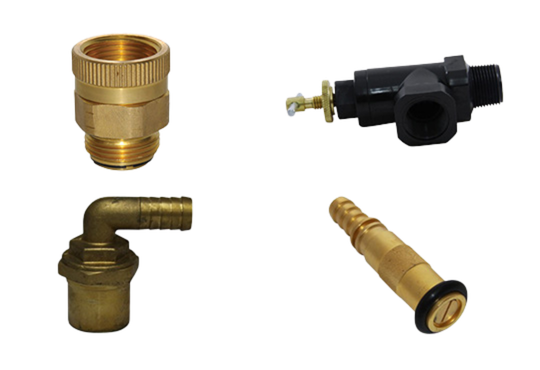

Inspecting hoses and fittings

Replacing worn nozzles

Storing equipment out of direct sunlight

Well-maintained boom sprayers deliver consistent performance and reduce downtime.

Choosing the Right Boom Sprayer for Your Needs

When selecting a boom sprayer, consider:

Size of the area being sprayed

Type of chemicals used

Terrain and access

Vehicle or mower capacity

Availability of spare parts and support

Australian-made or Australian-supported equipment is often preferred due to durability and ease of servicing.

Final Thoughts

A boom sprayer is one of the most efficient and reliable tools for large-scale spraying tasks. Its ability to deliver even coverage, reduce chemical waste, and improve productivity makes it an essential piece of equipment for agriculture, turf management, councils, and commercial operations.

With the right setup, calibration, and maintenance, a boom sprayer provides long-term value and consistent results in Australian conditions.

Select A Dealer

No dealer selected